Theia Vision System

Introducing Hellenic Systems Ltd, Theia Vision and Line verification solution.

The system uses the latest in camera and lighting technology and has advanced font detection and learning systems which requires very little font training.

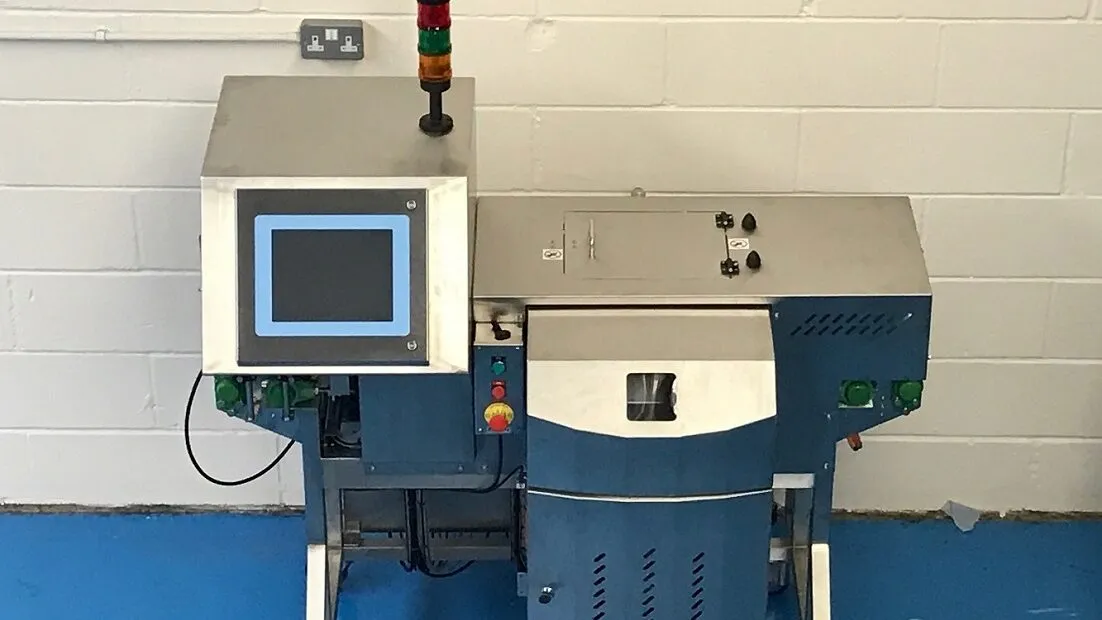

The system is available in a number of configurations;

a. Full conveyor with reject bin (as shown)

b. Canopy only (to fit existing conveyor systems)

c. Stand Alone (for off line pack inspection)

Theia will also control and set up a production line, and work to production orders. It is a single product that replaces up to three separate systems (Vision, LV, QA)

Theia System Facilities and Functions

- Processes up to 180ppm (8 inspection items)

- Self learning Font ability

- User interface for inspection region and label control

- Vision management studio to examine images and reporting (replicated on host servers)

- Reject bin support (mechanical or magnetic lock)

- User access control via barcode, RFID or PIN

- Factory Order processing functions

- Production line set-up and programming

- OCM / EOL equipment set-up and programming

- QA system built in

- Automatic ability to manage pack rotation

- Multiple CPU design to ensure that using the studio does not alter the performance

- FOPS8 integrated so that there is a single database to maintain and not multiple.

- Printing drift compensation (define a larger inspection area without performance reduction)

- Automatic camera placement to 0.1mm for focus control

OCR/OCV Analysis

Theia uses the latest OCR/OCV software tools in its construction. As a result the system can manage pack rotation (up to 180 degrees if needed) without the need to retrain or align. So if packs are not in the right orientation or have rotated, the systems performance is not compromised.

The font recognition software can process up to 25 fields per second, which can be improved with the upgrade of processor speed.

Programming the system is simply a matter of taking an image of the pack and drawing the boxes around the areas of interest, allowing for printing drift without the system rejecting a pack.

Reject Bin Control

The reject bin will push packs that fail inspection into the bin. This bin has door position detect, mechanical / magnetic locks and interlocks to prevent over load. The system also has a fail safe the if the lid is lifted, the system is shut down and air pressure removed. With the canopy only solution, integration with down stream reject systems is possible..

Reporting

The system reports every image back to a central database and stores the results locally. The FOPS8web system contains reporting facilities to be able to generate pack and QA reports for a given production order or batch. This then provides a complete trace reporting facility for a given pack, batch or order. All data is stored in an MS SQL compliant database.

Production Line Control

Theia is a lot more than just a vision inspection system, it is also a full production line and label verification system as well, that complies with a number of retailers codes of practice.

The system also covers;

- Verification of correct film being applied to a product

- Verification of the correct bottom label being applied to a product

- Automatic set up of any coding / printing / WPL printers (dates, price, text)

- Capture of image of pack label / film / OCM label from downtime terminal (if not using vision option)

- Verification of the flash labels (if not covered byvision camera)

- QA control at all stages / before release. Full audit of modifications,

- PPMH and OEE production dashboards for line efficiency reporting.

- Downtime recording using additional sensors on key equipment (e.g. thermoformers, gas machines, strapping machines)

- Programming of the EOL/OCM systems

Off line System

Theia can be provided as an off line pack inspection system. This has some added advantages;

- Both sides of the pack can be inspected.

- Product selection is done via a open order and/or by scanning of the EPOS / 2d barcode

- A weighing scale can be added to check declared pack weight (down to 1g or 2g)

- A more cost effective option where on line inspection is not required.

- Self positioning camera for pack size variation.

- Integrates with FOPS8/web

- Access via RFID, barcode, PIN

Canopy Solution

Theia can be provided as canopy solution where space is a premium, the key points of the solution are;

- A small footprint that can be modified and adjusted to fit existing production line conveyors

- Without a reject, but can be integrated with a down stream system

- More cost effective

- Simple to install and maintain

- Self positioning camera for pack size variation

- Integrates with FOPS8/web

- Access via RFID, barcode, PIN