FOPS8 Warehouse Management System

F8WMS is a new system desgined to work with third party conveyor and crane systems. To date Hellenic have installed 5 major retail meat packing factories. F8WMS integrates with the FOPS8 suite to provide closely automated processing procedures. The systems work on bar-code or transponder RFID technology for the rounting of crates and stack around the factory.The key features of the system are:

- FOPS8 Warehouse Management system add-on to FOPS8

- Designed to work with NAWI’s robotic control system

- Works on bar-code or transponder based crate stacks

- Delphi Developed application for easy maintenance and support

- The Main functions of the F8WMS are as follows;

- Goods-In (purchase order processing).

- Primal order scheduling

- Stock management (Primals in/out, finished product in/out)

- Factory Order processing (with WPL integration)

- Sales Order processing

- Warehouse performance statistics / reporting

- Purchase Orders as created within FOPS8 system and sent to the supplier.

- On arrival of goods, operator selects order from schedule list on the terminal or scans a printed bar-code on the delivery note.

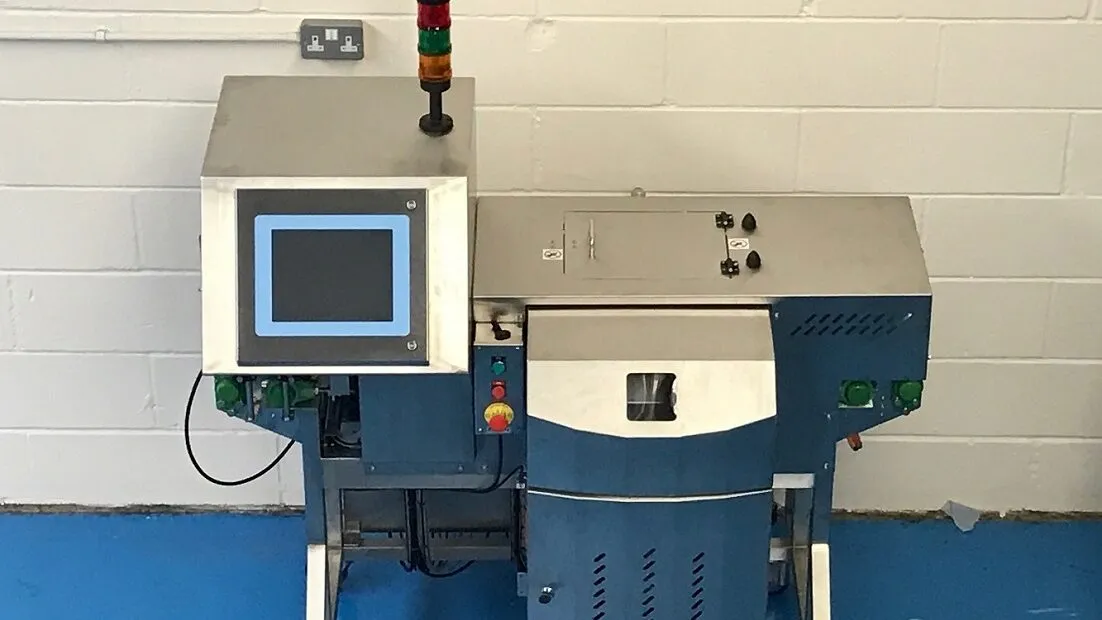

- F8WMS automatically scans and weighs the crate stack, checking for like products, Correct weight range and useable life (as set against the Purchase order).

- Product is automatically rejected or placed into stock locations.

- GRN notes and reject sheets are produced for supplier.

- Operator can over-ride system and allow acceptance of out-of-tolerance product.

- Variance reporting of declared and actual weight received.

- Real-time stock update.

- FOPS8 WMS Primal order schedule determines the issuing of primals to given Production lines against a production plan.

- This schedule can be manipulated on a manual or automatic basis.

- FOPS8 WMS delivers product into input lines in timed intervals.

- Primals as issued by Supplier, Product group and Kill date control.

- The origin of the meat is transferred to WPL systems (if connected) at line set-up time.

- As each crate is remove from the infeed, the stock is adjusted and the yield, line efficiency and WPL systems updated.

- Traceability is by supplier batch written directly to the WPL pack.

- Factory orders are production schedules created from sales orders, taking into account current finished stock.

- This is the total production requirement to be run for a given production period.

- Each line is assigned a given range of products, basedon the number of packs (or cases) in the desired production order.

- The terminals on the production line are used to select the required product to be produced that has been assigned to it or this is controlled by the Primal Issue terminals.

- Sales orders and entered into the SOP schedule (manually or via EDI / third party interfaces)

- Pallet planning is performed on an order / drop basis

- Stock is allocated dynamically to the sales orders (matching product type, life range)

- Orders are released to despatch through manipulation of the schedule.

- Product is delivered to the pallet placement operatives a pallet at a time.

- If any labels are missing, then can be replicated on demand.

- Once a pallet has been completed a pallet label can be produced and attached to the pallet

- Sales orders are updated and despatch documentation produced.

- The invoice is then raised and posted / emailed / EDI to the client

- FOPS8 exports invoice data to the ledger system

The key features of the system are:

Purchase Order Processing:

Quantity / quality checking. 100% bar-code or RFID transponder verification. Declared and actual weight verification. Verification of acceptable product life. Automatic allocation to stock locations. email/fax of GRN notes, interfaces with major ERP systems.

Stock Control:

Automatic stock verification, date rotation, dynamic stock allocation patterns. Controls issue of product to packing that ensures effective life. Warnings of pending out of date stock. Automatic selection of oldest stock.

Stock Issue:

Planning of batch control release to packing lines (supplier / product / date). Ensure that batch traceability can be maintained throughout the packing process. Product automatically issued to lines to match rate at which product is consumed.

Production:

Automatic scanning / reading of customer crates with intelligent put-away functions. 100% bar-code verification. Integration with FOPS8 planning module for packing line control. Batch control and traceability of product to suppliers purchase order and intake crate identification.

Despatch:

Planning allocation of products to despatch order schedules. Build by pallet stock extraction procedures with option to re-print missing end of case labels. Selection of product on date shelf life and time to delivery.

Remote Monitoring and Administration:

Warehouse state and performance can be monitored remotely. Individual parts of the system can be enabled or disabled to allow maintenance of the system to take place with minimum interference to normal operation.

Data Mirroring:

Critical warehouse data is automatically backed up in real-time to a standby computer allowing simple resumption of the system in the event of major hardware failure on the primary computer